Precision Forging Gears

Baoding Guokun Machinery and Baoding Guokun Export and Import Co., Ltd is a professional supplier and trading company of various bevel gears, spiral bevel gear, wenling spiral bevel gears, helical gears, worm gears and so on. The high quality forging bevel gears could be produced by hot forging, drop forging and precision machining method, which widely applicated on agricultural machinery, farm equipment, heavy duty truck, medium duty truck, light duty truck, tractor, car, automotive car etc. Baoding Guokun Machinery precision forging gears and hot forging gears are exported to USA, Canada, Germany, Italy, Australia, etc

China Forging Gear Factory

- Steel Forging: carbon steel, alloy steel, stainless steel, speical steel, tool steel, etc

- Steel forging process: open die forging, hot forging, free forging, mold forging and precision machining to achieve the dimensional accuracy.

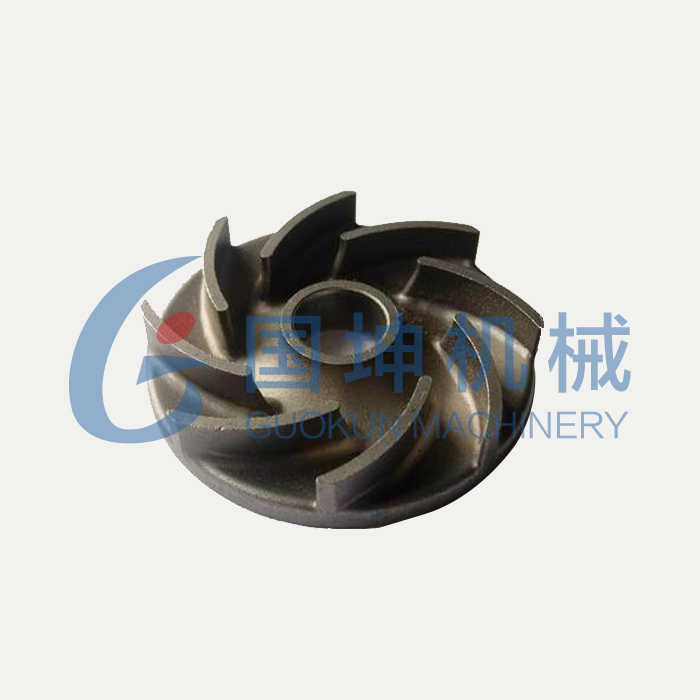

- Steel forging parts: gear, coupler, shaft, forging bevel gears, spiral bevel gears, wangling spiral bevel gears or other forged gears, helical gears, worm gears, near net forging gears

The Difference of casting & forging process

Forging Process

Forging is the process of forming and shaping metals through the use of hammering,pressing or rolling. The process begins with a cast ingot, which is heated to its plastic deformation teperature then upset between dies to the desired shape and size.

Forging can create a myriad of sizes and shapes with enhanced properties when compared to casting or assemblies.

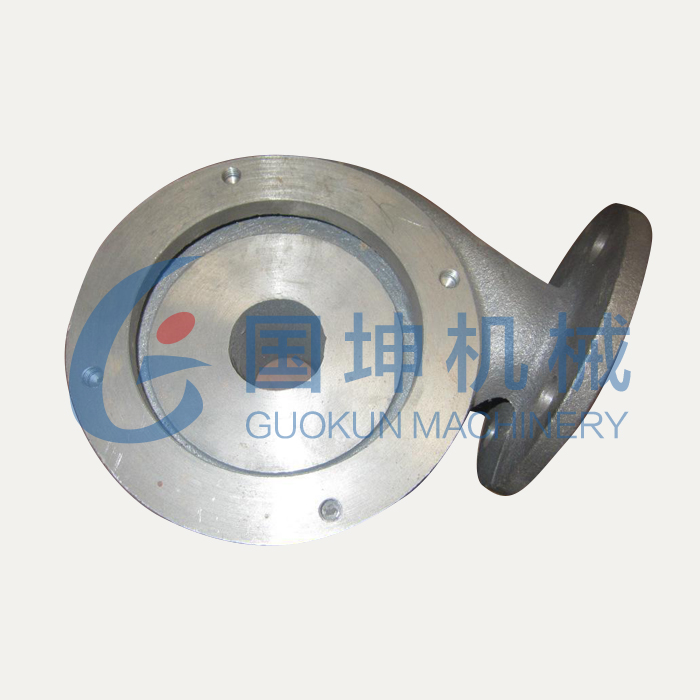

Casting process

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify, known as casting, which is ejected or brokedn out of the mold to complete the process.

Casting is most often used for making complex shapes that would be otherwise difficult or uneconomical to make by other methods.

If you need forging gear factory, China precision forging gears, precision forging gears, steel precision forging gears, precision forging gears factory, precision forging gears manufacturer, precision forging gears supplier, precision forging gears blanks, custom precision forging gears, customized precision forging gears, please feel free to contact gina@guokuncasting.com or gina.guokun@gmail.com or call us 86-18132789710.