Baoding Guokun, sand casting foundry in Baoding, China, uses sand casting process to manufacture a wide variety of metal products for many different industries, such as pump systems, valve, pipeline, heavy machinery, automotive replacement parts, agriculture components, etc. These sand casting parts are high quality and very cost effective.

Metal:

Sand casting, the most widely used casting process, utilizes expendable sand molds to form complex, metal parts that can be made of nearly any alloy. Baoding Guokun casting factory can offer the custom sand casting in the following metal:

- Gray iron sand casting, such as ASTM A48/48M, ASTM A159, BS EN 1561, DIN 1691, etc

- Ductile iron sand casting, such as ASTM A536, BS EN 1563, GB/T 1348-1988, etc

- Carbon steel sand casting, such as ASTM A29/A29M(1030, 1040, 1045, 1050, etc)

- Alloy steel sand casting, such as SAE J1249 (4140, 4340, 8140, 8630, etc)

- Stainless steel sand casting, such as ASTM A959 (304, 316, 316L, etc)

- Aluminum sand casting, such as ASTM B85-96(ASTM A356, A360, A383), JIS H5302:2000(ADC10.1, ADC12, etc), GB/T 15115-1994(YL102, YL112, etc)

- Bronze sand casting

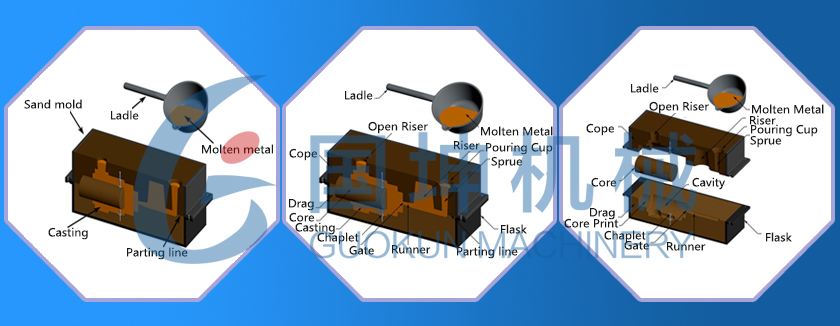

Sand casting process: six steps

- Place a pattern in sand to create a mold

- Incorporate the pattern sand sand in gating system

- Remove the pattern

- Fill the mold cavity with the molten metal

- Allow the metal to cool.

- Break away the sand mold and remove

Sand casting’s advantage and disadvantage

- Advantage

- Can produce a very large parts

- Can form complex shapes

- Many material options

- Low tooling and equipment cost

- Scrap can be recycled

- Short lead time possible

- Disadvantage

- Poor material strength

- High Porosity possible

- Poor surface finish and tolerance

- Secondary Machining often required

- Low production rate

- High labor cost

Application of sand casting process

Sand casting is used to produce a widely variety of metal components with complex geometries. These parts can very greatly in size and weight, ranging from a couple ounces to several tons. Some smaller sand cast parts include components as gears, pulleys, crankshafts, connecting rods, and propellers. Larger applications include housing for large equipment and heavy machine bases. Sand casting is also common in producing automobile components, such as engine blocks, engine manifolds, cylinder heads, and transmission cases.