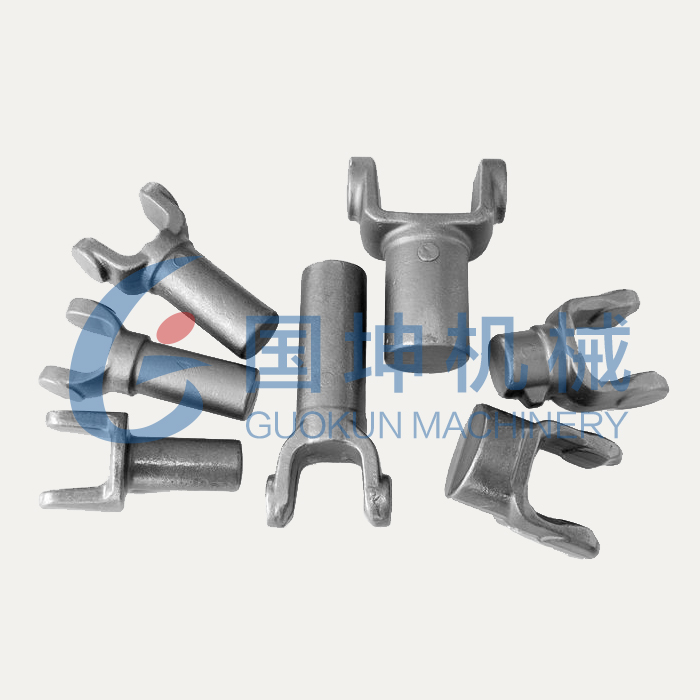

Aluminum casting parts

Guokun Machinery can produce and supply various aluminum casting parts, aluminum sand casting parts, aluminum die casting parts, Die casting manufacturer, die casting company, etc

Aluminum Alloy Characteristics:

High operating temperatures

Outstanding corrosion resistance

Lightweight

Very good strength and hardness

Excellent thermal conductivity

High electrical conductivity

Aluminum die casting

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. Aluminum die casting is with lightweight, high dimensional stability for complex shape and thin walls; good corrosion resistance; good mechanical properties; excellent thermal and electrical conductivity; retains strength at high temperatures.

Aluminum alloy: 413, 383, B390, A360, A380, A413

Advantage of aluminum die casting process

Excellent dimensional accuracy

Smooth cast surfaces

Thinner walls can be cast as compared to sand and permanent mold casting

Reduces or eliminates secondary machining operations.

Rapid production rates

Casting tensile strength as high as high as 60ksi

Casting of low fluidity metals

Aluminum sand casting

Sand casting, also know as sand molded casting, is a metal casting process characterized by using sand as the mold material.

Please send us the drawings to gina@guokuncasting.com or gina.guokun@gmail.com