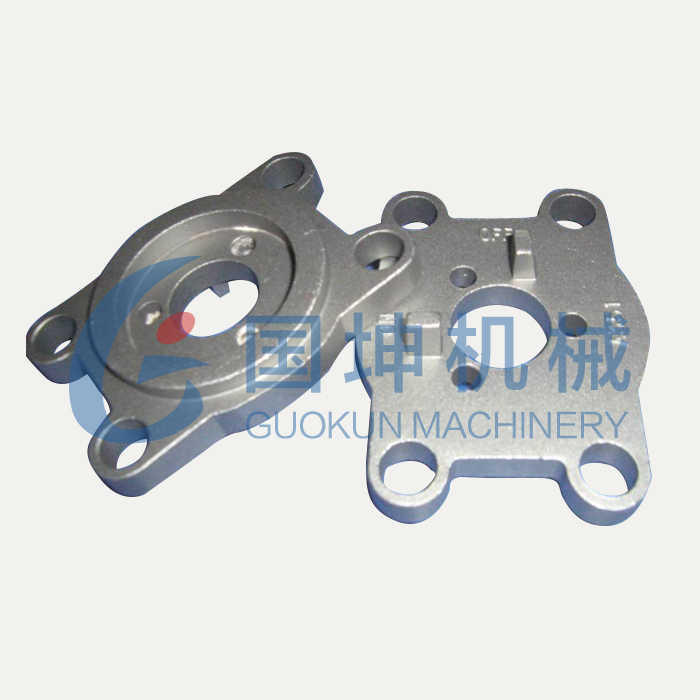

Silica sol casting

Silica sol casting is a typical investment casting process for stainless steel precision castings. The main process of silica sol casting is mold design firstly, then making wax, wax-tree assembling, then dewax, pouring, grinding, heat treatment, sand blasting, rough machining, precision machining, testing, lastly packaging. The weight of silica sol castings Baoding Guokun Casting Foundry can manufactured is 0.1kg-130kg.

Why choose Silica sol casting process?

- The casting surface of stainless steel silica sol casting parts looks very smooth and perfect, even meet 3.2 or better.

- The dimension accuracy of our silica sol precision casting is CT5-6, very high. So for some sections, there is no need to do machining, which will save much machining costs and time.

- Beside stainless steel, silica sol casting process is also used for casting small size alloy steels and carbon steels parts.

- Please note that the silica sol investment casting only suitable for small casting parts. If need big casting parts, we prefer to use sand casting process for you.

Our silica sol casting products are:

- Valve casting

- Pump castings

- Impeller castings

- Food Machinery castings

- Airplane casting parts

- Military casting components

- High Speed Train accessories

- Marine precision casting parts

You also can find lost wax casting process, water glass casting, precision investment casting, resin sand casting, green sand casting, shell mold casting, hot forging, heavy forging parts, cnc precision machining process in our China factory. We are committed to offer you the best solutions for your customized spare parts.