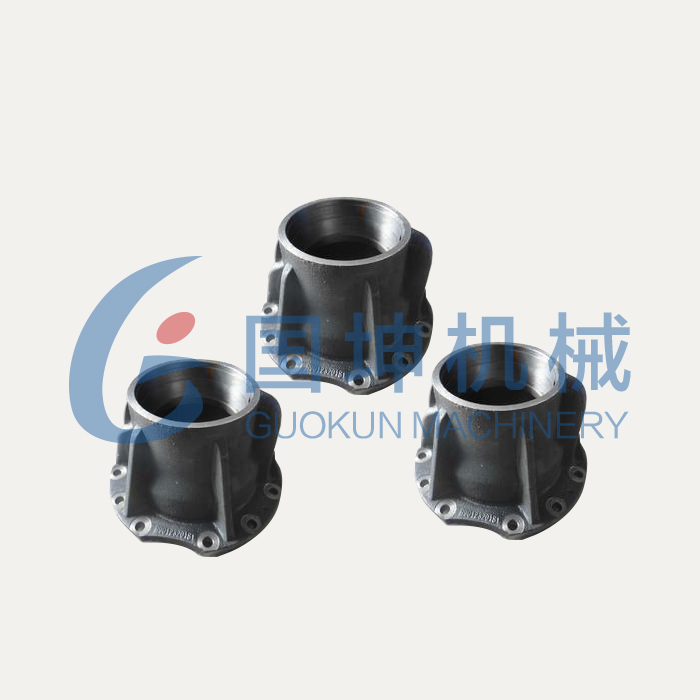

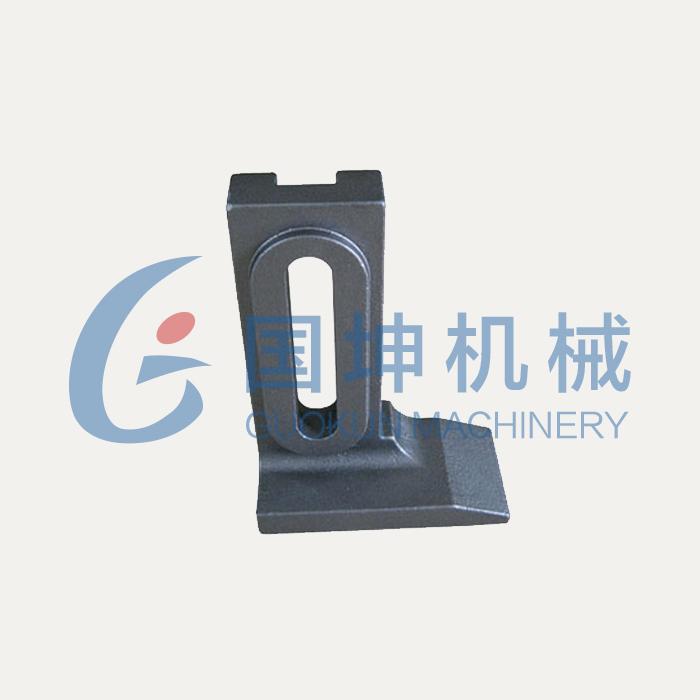

China No-Bake Sand Casting

Nobake is a casting process that involves the use of chemical binders to bond the molding sand. Sand is conveyed to the mold fill station in preparation for filling of the mold. A mixer is used to blend the sand with the chemical binder and catalyst.

No-bake sand casting process is widely favored for high precision casting in brass, bronze, aluminum and iron alloys, this process ensures accurate production of complicate designs. No bake process is an ideal process for high value, heavy and critical castings.

Other sand casting process we have:

| Item | Green Sand casting | Resin sand casting | Precoated Sand Casting or shell mold casting | Automatic Molding Line |

| Process | Green Sand Casting is the common sand castings made using wet sand or “green sand” molds. | Resin sand casting process is using the resin sand as the molding material. Resin sand is a kind of mixture of quartz sand and resin | The main molding material is the pre-coated phenolic resin sand, which is more expensive than green sand and furan resin sand. | Green sand molding line & resin sand molding line |

| Advantage | Usually for large steel castings and iron castings. | Suitable for custom castings with rough surface requirement and low unit cost. | high dimensional tolerance, good surface quality, and less casting defects | High production rate, only suitable for small & medium castings, require annual quantity |

| Casting Tolerance | CT11-12 | CT10-11 | CT8-9 | CT10-CT11 |

| Surface | ||||

| Weight | 5000kgs max. | 5000kgs max | 50kgs max | 10-50 kgs |

| Metal | Cast steel, Cast Iron, cast aluminum | Cast iron, Cast steel,cast aluminum, bronze | Cast steel, Cast Iron, cast aluminum, bronze | gray iron, ductile iron casting |

ASTM A48 Grey Iron Casting

Gray iron castings in ASTM A48 Class 20 are intended for general engineering use where tensile strength is a major consideration.

The grade is equivalent with grey irn GB/T 9439-1988 HT150, DIN 1691 GG15, JIS G5501 FC15, NFA32-101 Ft.15D, BS1452 Gr.150, ISO/R185 Gr.15 in China and other countries.

Chemical Composition:

C:3.0~3.6 S:≤0.12 P:<0.15 Mn:0.6~1.0 Si:1.4~2.0

Please note that this chemical composition is not standard, just from working experience of our iron casting foundry.

Mechanical properties

ASTM A48 Class 20 gray iron has a minimum tensile strength of 20,000 psi (140 MPa). Class 20 has a high carbon equivalent and a ferrite matrix.

If you need no-bake casting parts, no-bake sand casting, China no-bake sand casting, no-bake sand casting China, no-bake sand casting factory, no-bake sand casting supplier, no-bake sand casting company, cast iron no-bake sand casting, no-bake resin sand casting, please feel free to contact gina@guokuncasting.com or gina.guokun@gmail.com