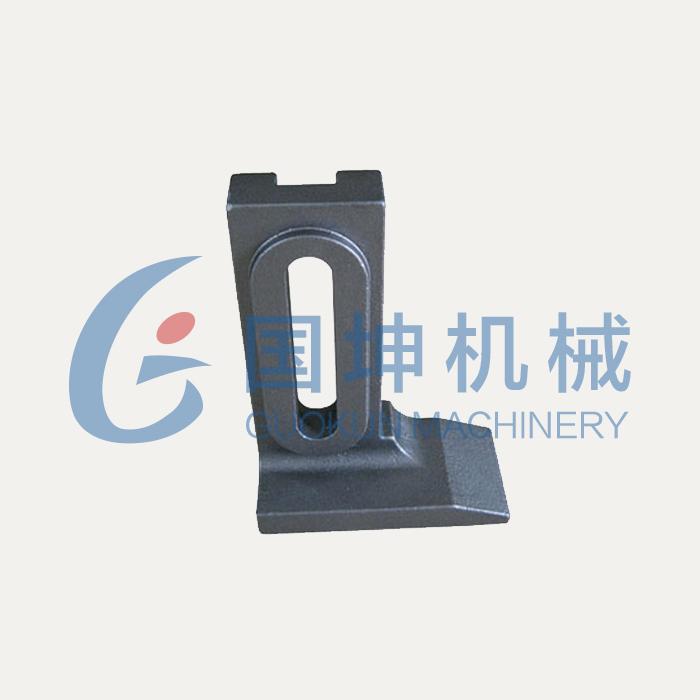

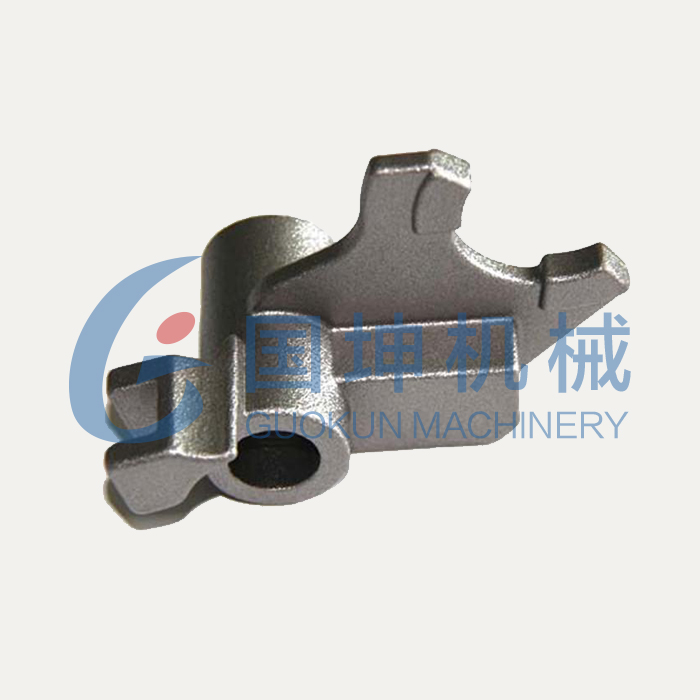

Bucket Teeth

Baoding Guokun have a wide variety of universal implements and attachments for all your equipment needs, such as bucket teeth and adapters for buckhoes, excavators, scrapers, loaders, digger, bulldozer and motor graders, etc

- Product Name: Bucket teeth, bucket accessories

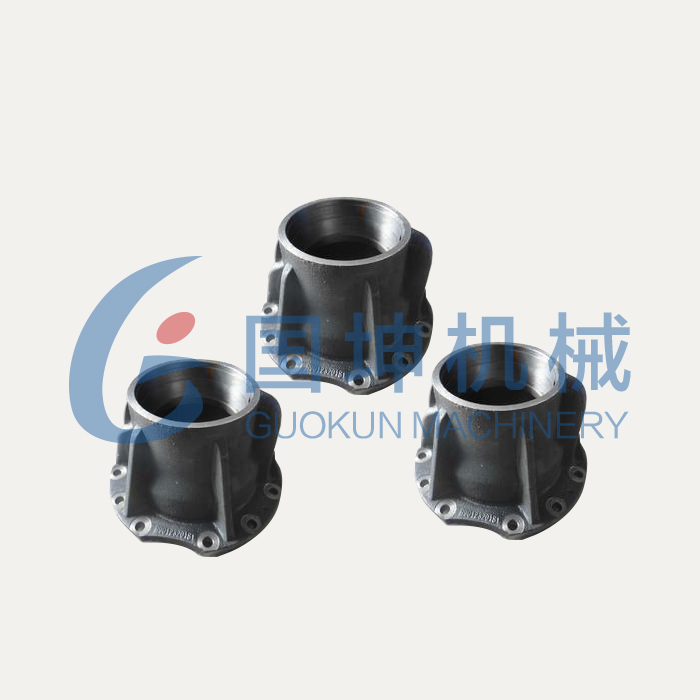

- Manafacturing process: investment casting, sand casting, shell mold casting, forging, etc

- Metal: High-Mn steel, wear resistant steel, low carbon steel, low alloy steel, etc

- Max. weight: 200 kgs

- Surface treatment: painting, power coating, etc

Shell Mould Casting is an expendable mold casting process that uses a resin covered sand to form the mold. As compared to sand casting, this process has better dimensional accuracy, a higher productivity rate, and lower labor requirements. It is used for small to medium parts that require high precision. Shell mold casting is a metal casting process similar to sand casting, in that molten metal is poured into an expendable mold. However, in shell mold casting, the mold is a thin-walled shell created from applying a sand-resin mixture around a pattern. The pattern, a metal piece in the shape of the desired parts, is reused to form multiple shell molds. A reusable pattern allows for higher production rates, while the disposable molds enable complex geometries to be cast. Shell mold casting requires the use of a metal pattern, oven, sand-resin mixture, dump box, and molten metal.